Industry:

Tunnel Industry

Transurban: Fulton Hogan EGIS : AJM United

Project Summary

Industry:

Tunnel Industry

Project:

M4, M8 & M5E Periodic Maintenance

Client:

Fulton Hogan Egis

Duration:

3 Years

Transurban: Fulton Hogan EGIS: M4, M8 & M5E Maintenance

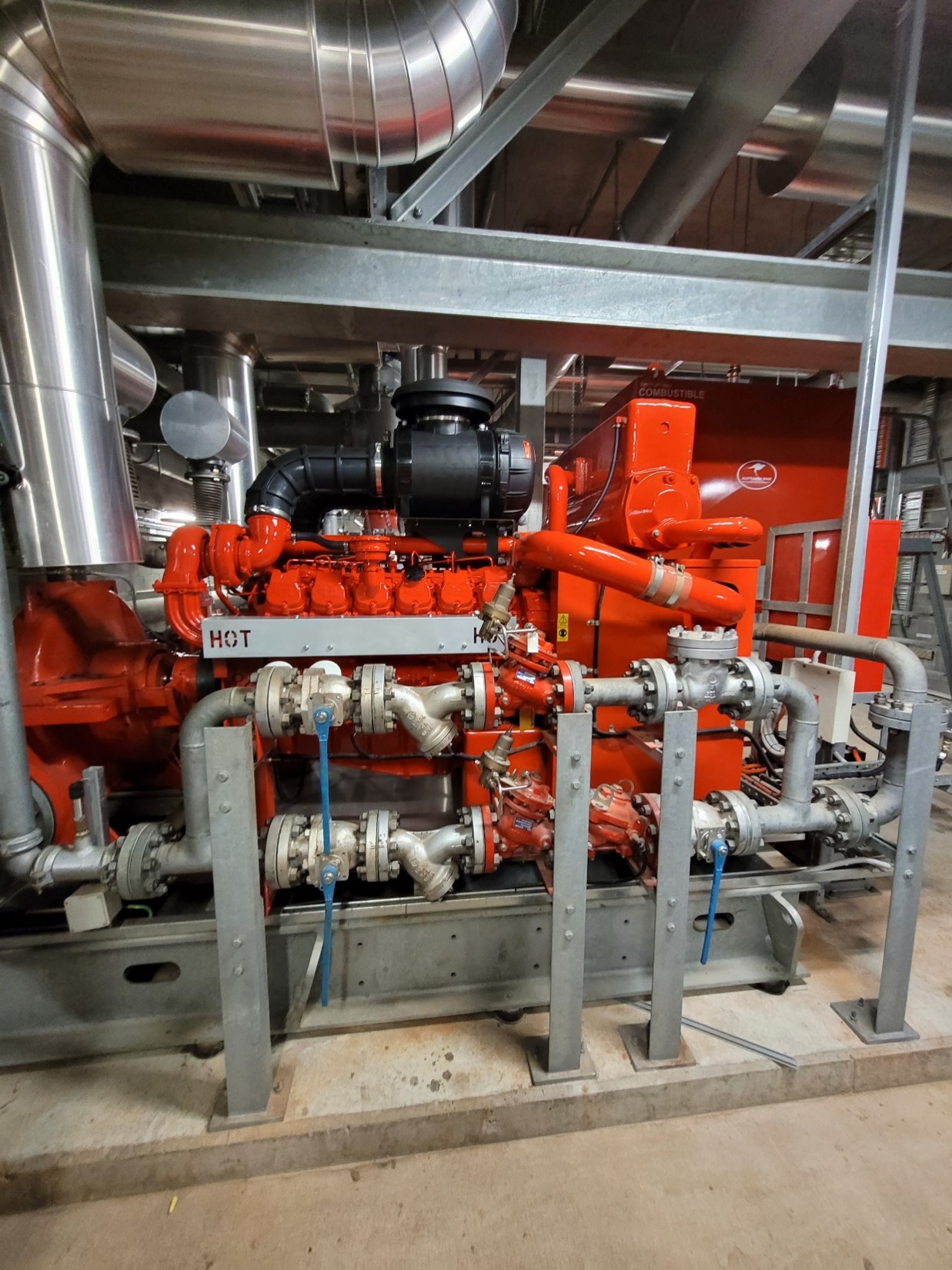

AJM United have been working together with FHE for over one year completing pump and pipe overhauls in wet and dry wells in Pits 1, 2, 4, 5 & 6 in the M5E, and conducting several condition assessments on existing tunnel assets, including fire deluge and hydrant pumps in the M4 & M8 tunnels, MOC4 & MOC8. Our first project was to overhaul Pit 5 wet well, including supply of new two off flygt pumps on periodic road closure, site measure of existing pipes to manufacture in 316SS, and replace with new.

Scope of works:

The condition of the pump station would have to be the worst we have ever witnessed in more than 20 years of working with these kinds of assets. All parts are heavily corroded beyond their serviceable life and had the potential to fail at any moment without warning. The guide rods and pipework for the pumps are so corroded that if an attempt to lift the pumps out was made, the surrounding items would break and collapse leaving the station inoperable.

A detailed methodology was required for the pump changeout to mitigate the risk of a station total failure during the change out. We allowed one shift to test and time the lockout and isolation protocols to ensure efficiency when conducting the overhaul. Bypass lines were installed to ensure one pump was always in operation.

The change out was done in stages and over three different road closures with four shifts per closure with great success and ZERO Harm to all involved on the project. The most recent feedback from the FHE is that the pumps are operating at a much higher efficiency rate with no deficiencies to date. AJM have also received emergency call out to assist with pump failure and installation.